What Really Happens Inside Reinforced Concrete

Concrete looks simple from the outside: a grey beam, a slab, a column. Inside, the behaviour is much more interesting. Concrete and steel work together deliberately so the structure can carry heavy loads, control cracks, and remain serviceable for decades.

This post walks through how plain concrete behaves, why we add reinforcement, what happens when a beam cracks, and why shear and joints matter so much.

Concrete on its own

Concrete is one of the most widely used construction materials in the world. It is easy to shape, relatively cheap, and the ingredients are available almost everywhere.

Properly designed and constructed, it gives excellent durability and economy for buildings, bridges, and civil engineering structures.

Mechanically:

Compressive strength is usually about 30 to 50 MPa for regular structural mixes, and can go much higher for special concretes.

Credit: Ultratechcement.com

Tensile strength is very low in comparison, typically about 3 to 5 MPa.

Credit: Mdpi.com

Elastic modulus is around 30,000 to 35,000 MPa in short-term compression.

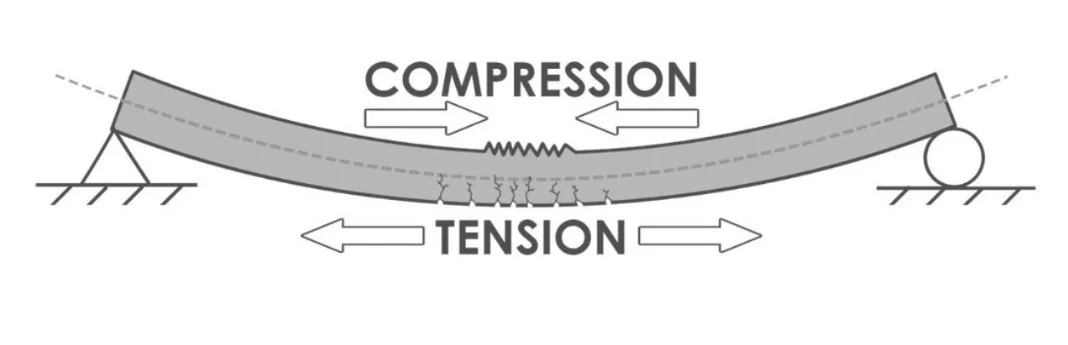

So in compression, concrete is strong and stiff. In tension, it is weak and brittle.

Credit: researchgate.net

On top of that, concrete exhibits creep and shrinkage, which increase deflections and strains over time. In practice, this means concrete alone is not stiff enough or reliable enough to carry significant tensile forces in structural members.

In real beams, slabs, and columns, the combination of external loads, temperature change, and foundation movement creates local tensile zones.

Even if we used plain concrete, those tensile regions would crack, and the member would not perform as required.

Why we add steel reinforcement

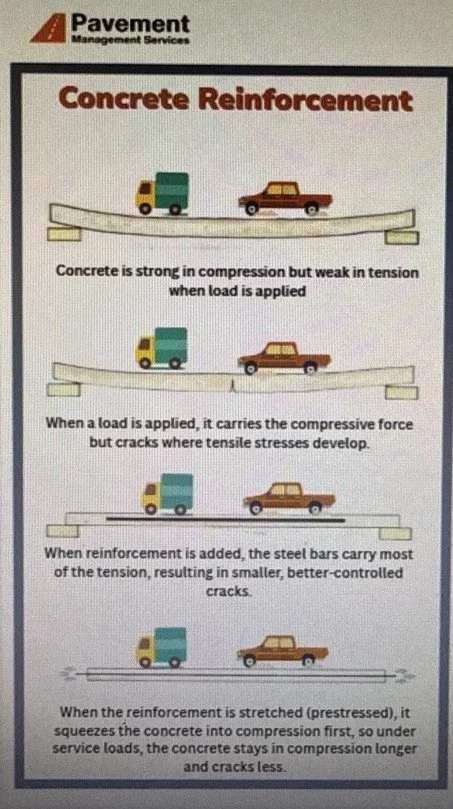

The primary deficiency in concrete is its low tensile strength. We overcome this by adding steel reinforcement in the regions where tension is expected.

A few key ideas govern this partnership:

Concrete carries compression.

Steel carries tension.

Bond between them allows forces to transfer back and forth so they act as one composite material.

Because concrete and steel have similar coefficients of thermal expansion, they expand and contract together with temperature changes. This compatibility means the bond between them is not constantly fighting thermal movement.

Reinforcement is usually provided as thin steel bars placed in zones where tensile stresses will develop.

When designed correctly, concrete and steel together behave as a single composite section that is far more efficient than either material alone.

What happens when a reinforced beam bends

Consider a simple reinforced concrete beam carrying a uniformly distributed load.

At low load, the whole section is uncracked. Concrete takes both compression and tension, and the steel stress is small.

As load increases, the bottom fibres go into tension. Once the tensile stress in the concrete reaches its modest tensile strength, cracks form at the bottom.

After cracking, the concrete in the cracked tension zone can no longer carry tension. The tensile force is transferred into the steel through bond.

The steel now carries the internal tensile force T, while the concrete above the neutral axis carries the compressive force C. Together they form a couple that resists the bending moment M.

An important detail: the steel in the cracked region does not stop cracks from forming. That is not its purpose. Instead, it:

Resists the internal tensile force so that the section can still carry load after cracking.

Controls crack width so that cracks remain fine and well distributed rather than wide and localised.

At full working load, a reinforced beam almost always shows a pattern of excellent flexural cracks, sometimes called hair cracks. Under close inspection, these extend some distance into the depth of the section, but a solid compressive block of concrete remains above the tips of the cracks.

This is why design is based on a cracked section on the tension side. We assume the concrete there is ineffective in tension and let the reinforcement do that work.

Where to put the steel and why detailing matters

The function of reinforcing steel is essentially twofold:

Carry the internal tensile force in the member.

Prevent tensile cracks from becoming too wide.

To do that, reinforcement must be placed where the tensile stresses actually occur.

In a supported beam with positive bending, that is, near the bottom face.

In a continuous beam, tensile zones appear at mid span in one span, and at the top near interior supports in negative moment regions. So bars are needed near the bottom in positive moment zones and near the top in negative moment zones.

If bars are not placed in the correct tension zones, the member may crack in regions with little or no reinforcement, leading to poor performance and possible failure.

Shear, stirrups, and inclined cracks

Bending is only part of the story. Real beams also carry shear.

High shear forces near supports tend to produce inclined cracks that start at the tension face and propagate toward the compression zone. To prevent sudden shear failures, provide transverse reinforcement:

Regularly spaced vertical bars or closed links are called stirrups.

These stirrups are placed to intersect any potential inclined shear cracks.

Longitudinal bars and stirrups are often tied together into rectangular cages for ease of construction.

In practice, many beam failures begin as shear or anchorage problems near supports. This is why stirrup detailing, anchorage, and joint design are critical parts of reinforced concrete design, not just the main flexural reinforcement.

Slabs and columns

Floor slabs

Floor slabs supported at corners or edges bend in two directions. Tensile forces develop along both main span directions, so bars are placed at right angles to each other to resist tension in both directions. For convenience, welded mesh is commonly used as slab reinforcement.

Columns and compression members

Although steel reinforcement is primarily used for tension, it also plays an essential role in compression members.

Concrete is strong in compression, but steel is even stronger. Adding longitudinal steel can boost the compressive resistance of heavily loaded columns.

Longitudinal bars also provide a path to carry bending moments that produce tensile stresses on one side of the column.

Transverse ties or spirals hold the longitudinal bars in place during casting and help prevent them from buckling outward under compression.

So even in members that are primarily in compression, steel reinforcement contributes both strength and stability.

Key takeaways

Putting it all together:

Plain concrete is strong in compression but weak and brittle in tension, and long-term effects like creep and shrinkage reduce stiffness.

Steel reinforcement does not remove tensile forces. It gives them a safe path, carrying tension after the concrete cracks and keeping crack widths under control.

In bending members, concrete carries compression, steel carries tension, and the design is based on a cracked section on the tension side.

Shear and joints are frequent weak spots. Stirrups, proper anchorage, and good detailing near supports are essential to prevent brittle failures.

Slabs and columns use reinforcement to carry biaxial bending, control cracking, increase compression capacity, and keep longitudinal bars stable.